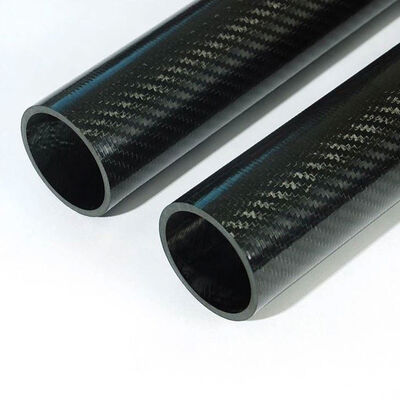

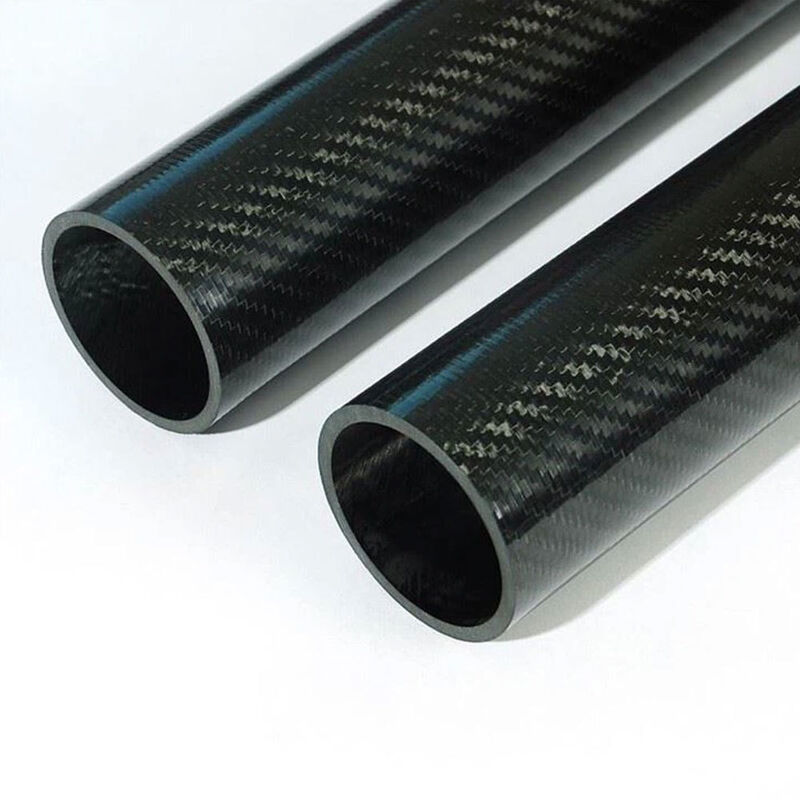

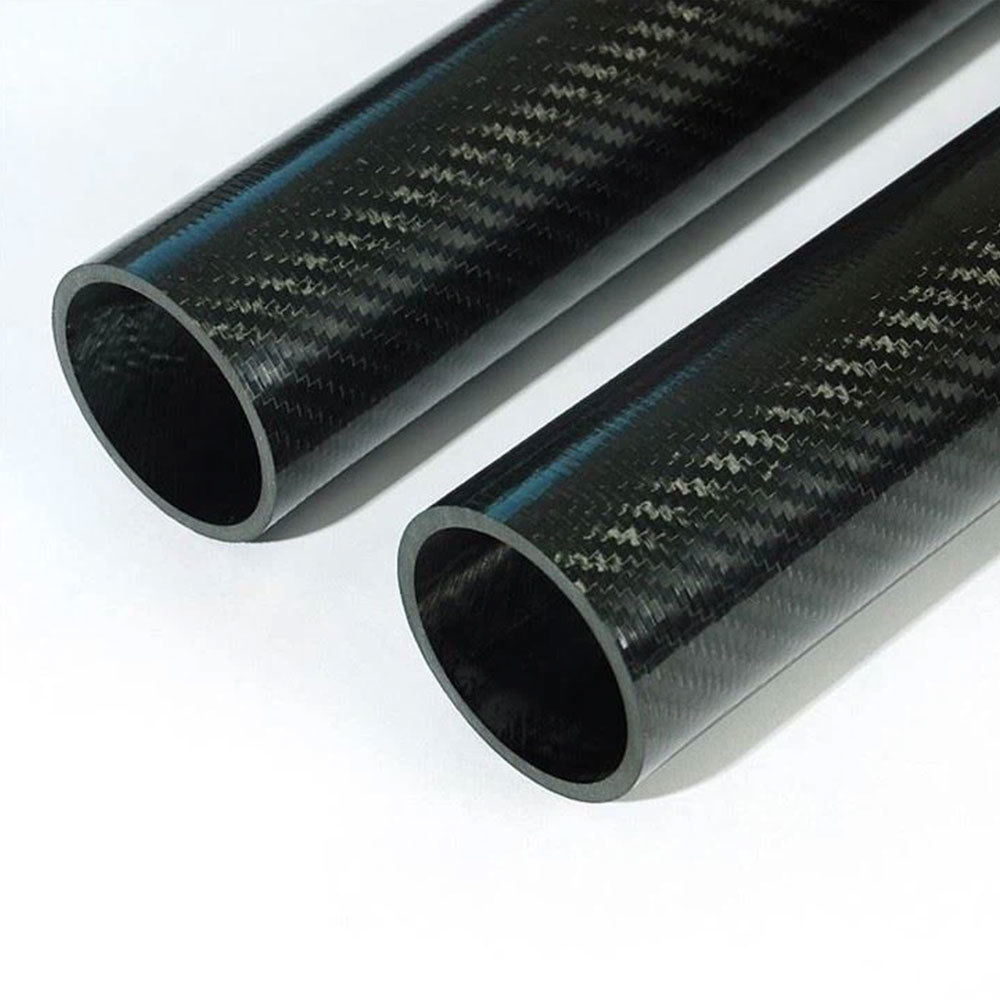

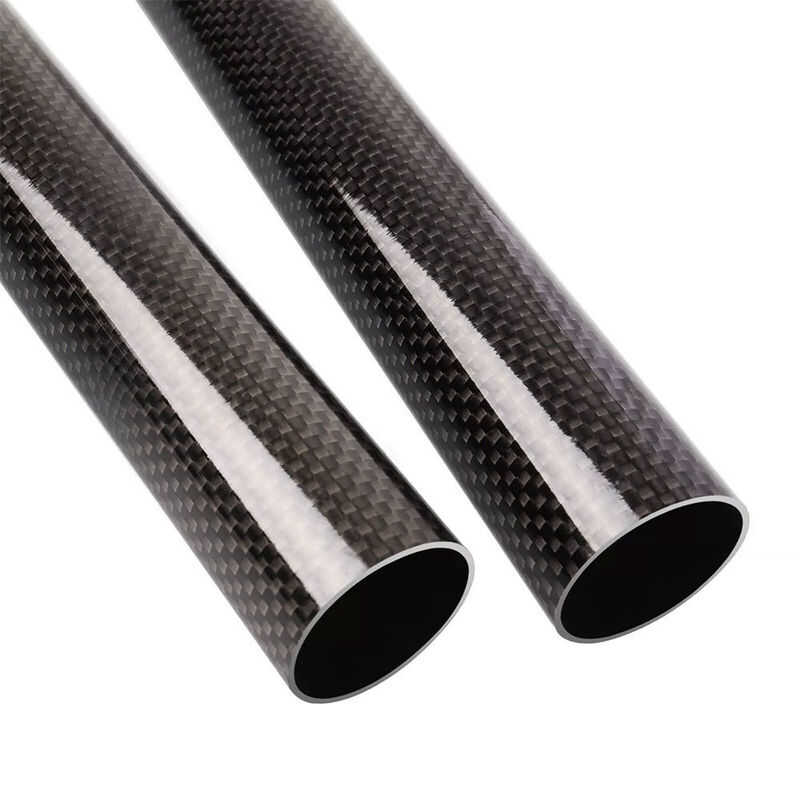

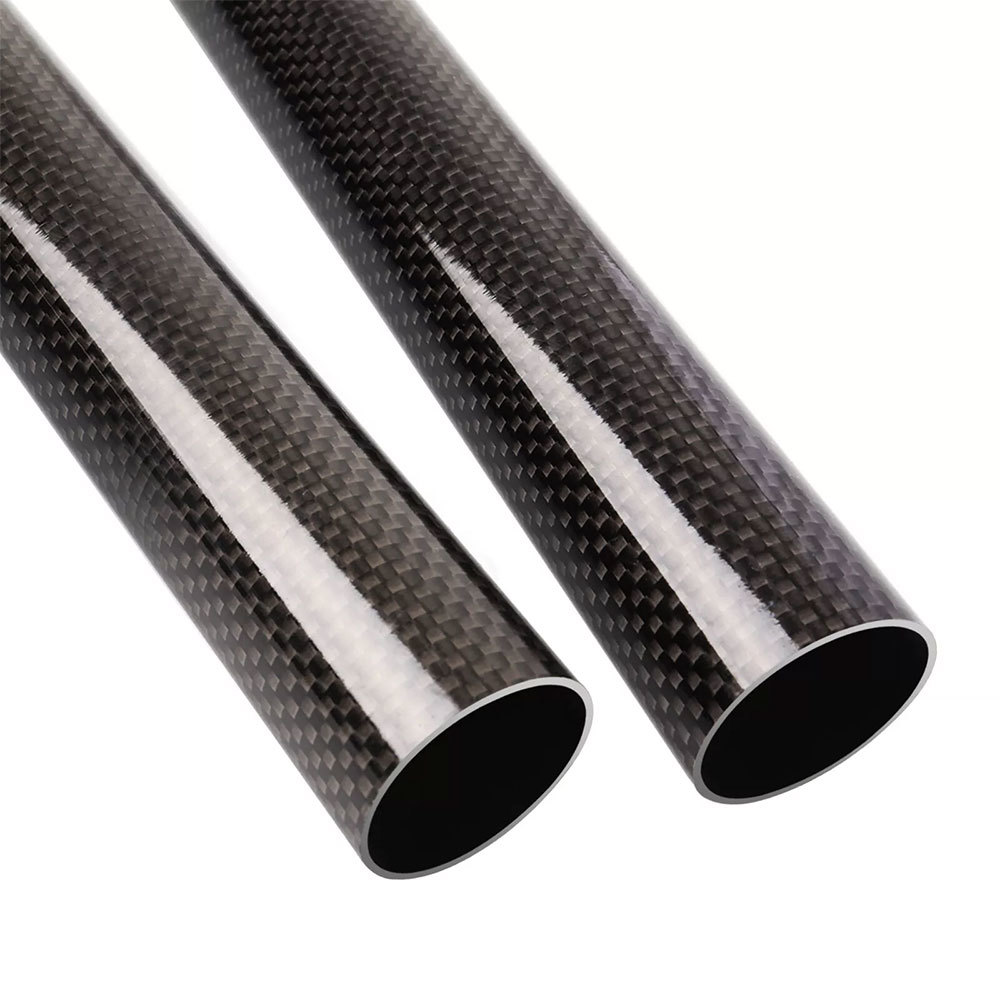

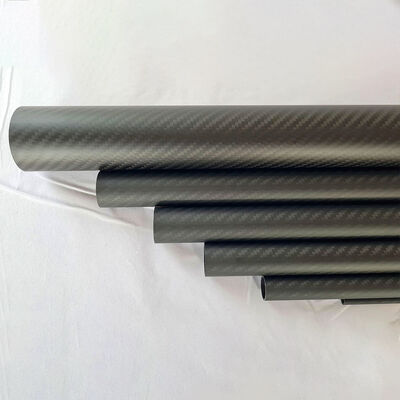

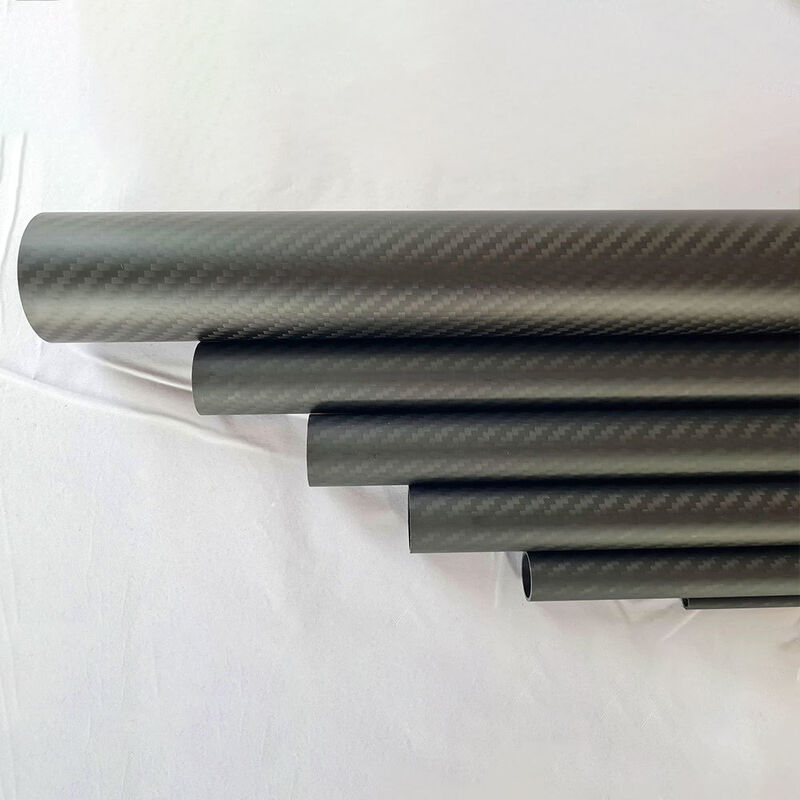

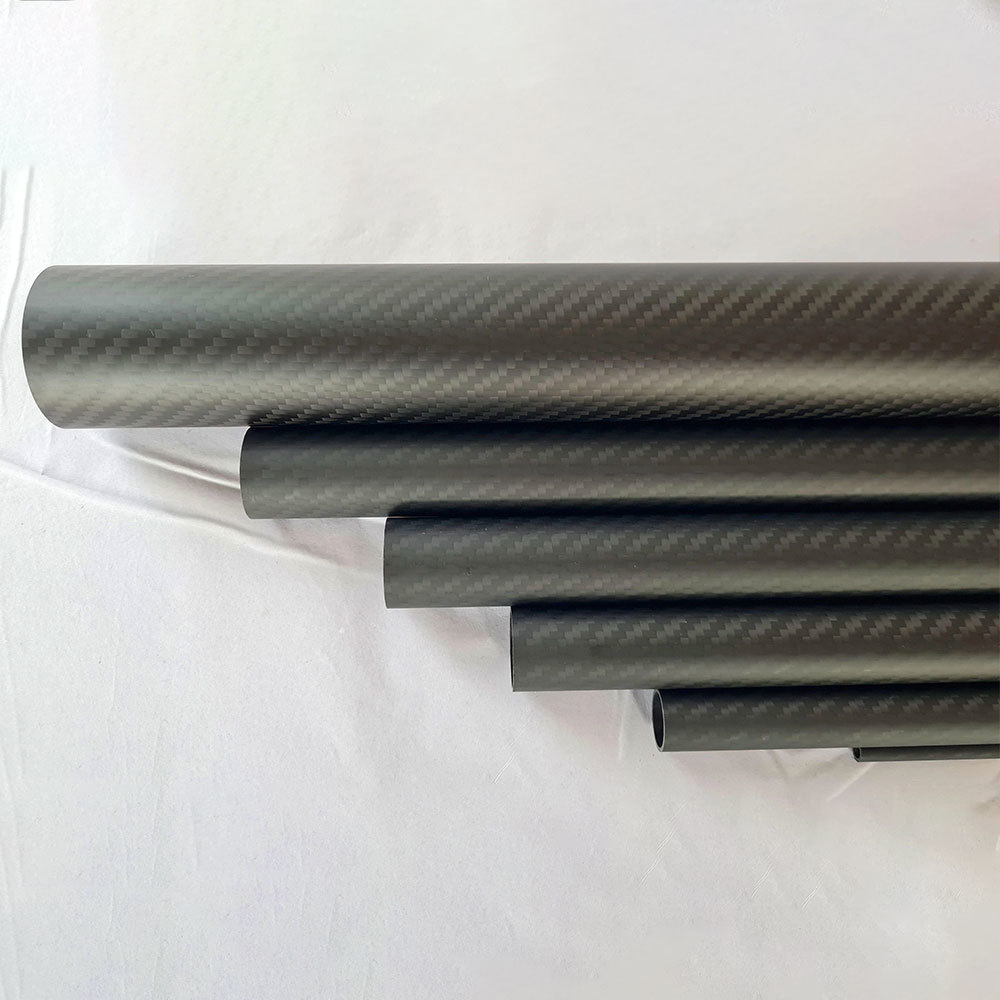

High Stiffness Round Shaped 100% 3K Roll Wrapped Carbon Fiber Tube

メッセージ

折り返しご連絡いたします!

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。

メールを確認してください!

メールを確認してください!

送信

より多くの情報はより良いコミュニケーションを促進します。

氏

- 氏

- ミセス

OK

正常に送信されました!

折り返しご連絡いたします!

OK

メッセージ

折り返しご連絡いたします!

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。

メールを確認してください!

メールを確認してください!

送信